Orange County Grease Interceptor Service

Commercial Grease Interceptor Cleaning Services for Restaurant Grease Removal in Orange County

A Grease Interceptor is an essential plumbing device of great magnitude designed to manage the flow of over 50 gallons per minute efficiently. It outperforms standard grease traps in both size and efficiency.

We’re here 24/7 for you

+75 Google reviews

What Is Grease Interceptor Cleaning?

Restaurants are prolific producers of biological waste. In fact, nearly 40% of the waste generated annually comes from restaurant operations. What’s surprising is that a significant portion of this waste originates from the kitchen sinks and drains.

A Grease Interceptor, this plumbing marvel capable of handling over 50 gallons per minute, plays a pivotal role in this scenario.

Interceptor Cleaning

This critical equipment is strategically placed in the sanitary drainage system outside the restaurant building or commercial food establishments. Its primary purpose is to collect fats, oil, and grease (FOG) from the wastewater.

The disposal of FOG directly into the sewage system poses serious environmental hazards. Recognizing this, the Environmental Protection Agency (EPA) has explicitly prohibited any such discharge into stormwater collection systems. Furthermore, state laws necessitate periodic cleaning of these interceptors.

At Royal Pumping & Jetting, we are your trusted partner in ensuring eco-friendly maintenance and Professional Grease Interceptor Cleaning of your Restaurant and Hotel Grease Interceptor. Our goal is to not only help you comply with regulations but also relieve you of this substantial concern. Click here to schedule an evaluation visit.

How Does a Grease Interceptor Work?

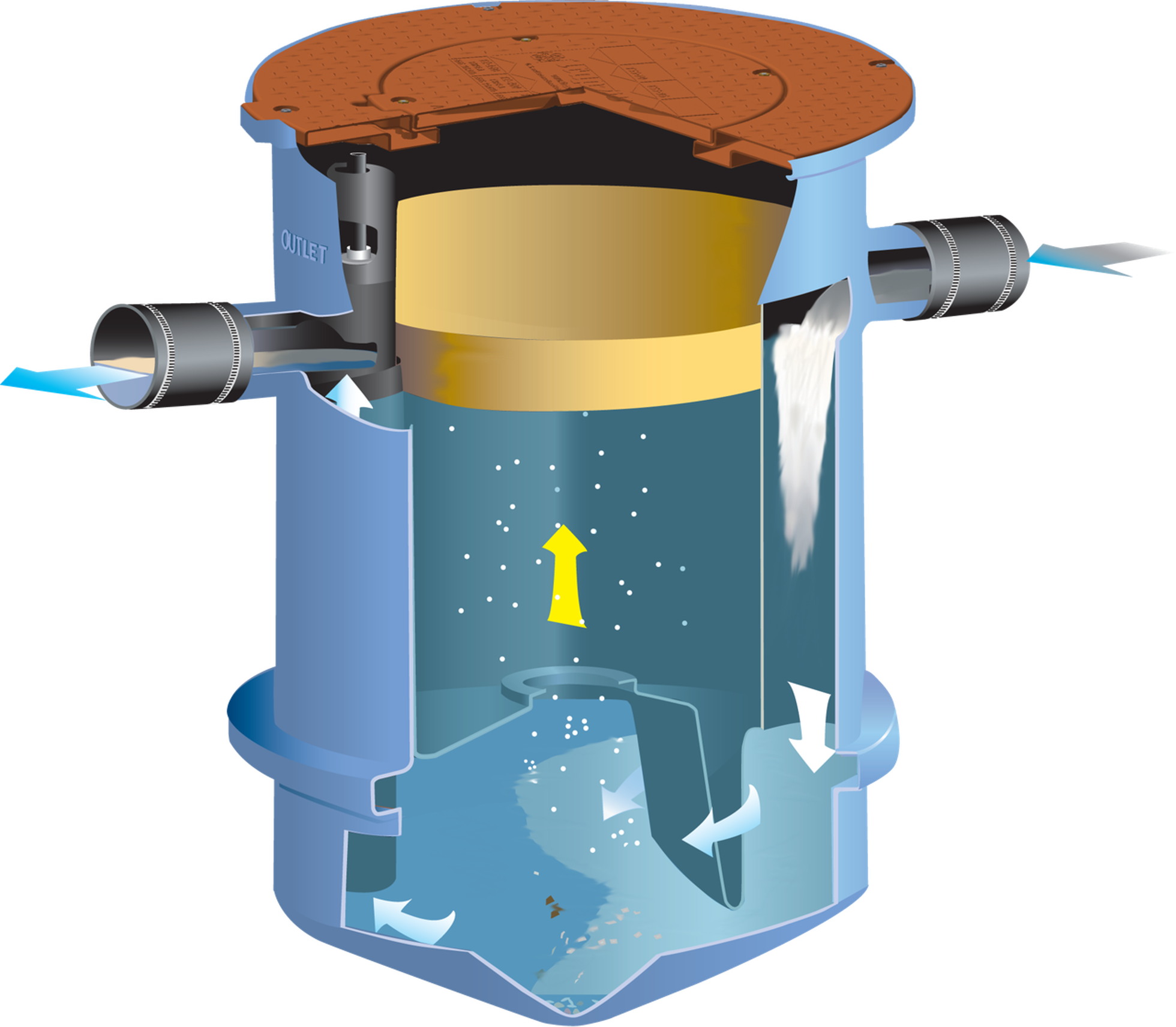

When employees wash dishes, food residues flow through the drainage pipes. These residues enter the Grease Interceptor through an inlet equipped with a flow regulation device.

Inside the Grease Interceptor tank, animal fats and vegetable oils, which are 10% to 15% less dense than water, remain afloat. These substances, collectively known as FOG (Fats, Oils, and Grease), accumulate behind retaining fittings and a partition panel that separates the system compartments.

Royal Pumping & Jetting’s role encompasses two crucial aspects during routine Grease Interceptor maintenance. Firstly, we excel at removing accumulated FOG to ensure efficient operation. Secondly, we focus on preventing FOG from progressing downstream, where it could potentially block the city’s sewage pipes.

Simultaneously, the Grease Interceptor traps food residues at the system’s bottom.

In addition to these vital tasks, we diligently inspect, report on, and provide maintenance for all Grease Interceptor components. We aim to keep your Grease Interceptor in impeccable operational condition, preventing potential issues resulting from failure or improper installation, such as damage to the baffle T or bracket tubing.

To ensure optimal performance and longevity for your Grease Interceptor, place your trust in Royal Pumping & Jetting.

Where Do Restaurants Collect FOG?

Employees in restaurants, hotels, and other food and recreation service establishments must refrain from disposing of water containing FOG residues directly into the floor drainage systems.

In many cases, floor drainage pipes directly connect to the sewer without any form of filtration. Consequently, wastewater containing FOG contributes to environmental contamination and adheres to the city’s sewage infrastructure, leading to system blockages.

The practice of pouring FOG-laden water directly into the sewage system poses a significant threat to public service and constitutes a violation of state laws.

State laws mandate the installation and proper maintenance of a grease trap or grease interceptor in food facilities and restaurants to correct grease and waste disposal and avert sewer overflow issues.

Royal Pumping & Jetting offers comprehensive guidance to food facility and restaurant owners regarding best practices for residual water disposal. Click here to schedule an evaluation visit.

Who Is in Charge of FOG Disposal Compliance Inspections?

The California Department of Food and Agriculture (CDFA) serves as the authority responsible for overseeing the safety and quality of the food supply across the state. Additionally, the CDFA supervises compliance with regulations governing the removal and disposal of FOG waste.

CDFA inspectors stationed in various cities are tasked with scrutinizing and supervising grease interceptors at restaurants and food production facilities. Failure to maintain a grease interceptor in satisfactory operational conditions or poor maintenance practices could result in fines.

Royal Pumping & Jetting holds the distinction of being licensed and approved by the CDFA as inedible kitchen grease waste haulers. Our services aid restaurant owners avoid administrative fines that could tarnish their reputation and adversely affect their business finances. Click here to schedule an evaluation visit.

How to Schedule Grease Interceptor Cleanups?

Grease Interceptors possess a significantly larger capacity than grease traps. However, it remains crucial to implement a well-structured maintenance plan that factors in the average time it takes for food solids to accumulate or follows a servicing schedule with visits every three months.

It’s important to note that a clogged Grease Interceptor can obstruct the plumbing lines and cause reverse backups of solids into the kitchen, leading to unpleasant odors and service delays. Such situations can also lead to customer complaints.

As a trusted grease trap service company in Orange County, Royal Pumping & Jetting is pivotal in helping you avert more significant problems by proactively preventing unfavorable situations that could tarnish your business’s reputation. Click here to schedule an evaluation visit.

Get a quote at 949-201-5714. Schedule Grease Interceptor Cleanups

What Are the Benefits of Scheduling Routine Grease Interceptor Cleanups?

Vegetable oils decompose within approximately 28 days, and the rancidity of animal fat and grease, combined with microbial food rotting, can lead to unpleasant odors. This situation can escalate when the Grease Interceptor is overfilled.

To counter these adverse effects, restaurant kitchens, and food facility managers should diligently monitor and schedule periodic restaurant grease trap and grease interceptor maintenance cleanups. This helps prevent sewer clogs, backup reversions, unpleasant odors, fines, and customer complaints.

But are there other hidden benefits to Grease Interceptor cleanups? Indeed, several advantages can positively impact your food business:

- Reduces the risks of diseases caused by disease-causing pathogens.

- Reduces the proliferation of rodents and other pests.

- Eliminates spillages on the floors and adjacent areas resulting from improper FOG management.

- Minimizes the occurrence of unattractive grease spots on the lot floor, walls, or neighboring areas like the parking lot.

- Reduces corrective repair expenses.

- Helps maintain a clean environment.

- Provides safety, well-being, and hygiene for employees.

Royal Pumping & Jetting assists you in addressing unnoticed collateral damages, such as pest proliferation, unsightly surroundings, and health and environment-related concerns arising from the improper handling and treatment of FOG. Click here to schedule an evaluation visit.

Wide range of service offerings for clients

A grease trap is a plumbing device that is created to capture and divide grease, oil, and other firm materials from wastewater to prevent it from entering the sewer system.

A grease interceptor trap is a plumbing device specially designed to capture and split grease, oil, and grease (FOG) from wastewater generated in commercial kitchens and food service establishments.

Used Cooking Oil Disposal refers to the process of safe and responsible disposal of used cooking oil created in commercial kitchens and food service establishments.

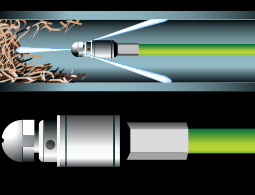

The hydrojet is a method of cleaning and unclogging pipes that uses high-pressure water. With specialized equipment that shoots water through a nozzle into the pipes, removing clogs, debris, and buildup along the pipe walls.

Efficiently managing the disposal of inedible food through eco-friendly recycling and destruction processes to minimize waste and environmental impact.

Grease trap fixing refers to the process of fixing or restoring a malfunctioning grease trap system. Repair or Replace: If there are damaged or malfunctioning parts in the grease trap, they will be repaired or replaced.

Grease interceptor trap repair is vital to efficient wastewater management, preventing clogs or clogs in the plumbing system, and complying with environmental regulations. This involves repairing or restoring a grease interceptor trap system that not working properly

High-pressure washing is a surface cleaning method that uses a powerful, high-pressure water jet. It involves the use of specialized equipment that generates pressure to effectively remove dirt, grime, mold, and other contaminants from various surfaces.

Full-service plumbing is a wide range of services provided to address various plumbing needs. This service is essential to maintaining a healthy and efficient plumbing system, ensuring proper flow, preventing water damage, and promoting overall health and stability

Frequently Asked Questions

A grease interceptor trap, or grease trap, is a vital plumbing device designed to intercept and collect fats, oils, and grease (FOG) from wastewater before it enters the municipal sewer system. It is an indispensable tool for managing FOG in commercial kitchens and food establishments.

It is essential to have a grease interceptor trap to prevent FOG from clogging municipal sewer lines and causing backups or overflows. Additionally, it plays a crucial role in safeguarding the environment by reducing the amount of FOG that enters waterways.

The frequency of a Professional Grease Interceptor Cleaning or a grease trap cleaning service depends on factors such as the trap’s size, the amount of FOG generated, and local regulations. Typically, these traps should undergo professional cleaning at least once every 90 days, although some may require more frequent maintenance.

Neglecting regular cleaning of your interceptor trap can lead to clogs in the plumbing system, causing backups. This can result in costly repairs and potential fines from local authorities for non-compliance with environmental regulations.

Failure to properly maintain a grease interceptor trap can lead to the accumulation of FOG, resulting in blockages in sewer lines. This can lead to expensive repairs, fines, and even legal action.

It is not recommended, as it can be dangerous and messy. It is best to hire a professional for proper cleaning and responsible disposal of the collected waste. For more information, please contact us.

Proper maintenance includes regular cleaning of the trap, responsible disposal of FOG, and vigilant monitoring for any signs of damage or blockages. Additionally, it is crucial to follow local regulations and guidelines for grease interceptor trap maintenance.

An interceptor trap is larger and more robust than a grease trap, capable of handling larger volumes of wastewater. It also removes larger amounts of sediment and debris, in addition to grease and oils. Grease traps, on the other hand, are typically smaller and designed primarily for the removal of grease and oils.

No, it is not recommended to pour chemicals down the drain, even if you have an interceptor trap. Some chemicals can cause damage to the trap and plumbing system. Always follow proper disposal procedures in accordance with local regulations to ensure the continued effectiveness of your interceptor trap.

We’re Ready To Help You!

Get a Quote

How does it work?

- Fill out the form and get a quote.

- You´ll receive a quote within 16 hours

- We do the job. You pay later.